The world of motion-controlled gaming and VR experiences has evolved dramatically in recent years, with 9-axis inertial measurement units (IMUs) becoming the gold standard for precise movement tracking. These sophisticated sensor arrays combine accelerometers, gyroscopes, and magnetometers to create a comprehensive picture of controller orientation in three-dimensional space. However, what many users don't realize is that the magic of seamless motion tracking begins long before they pick up their controller - it starts with meticulous sensor calibration.

Understanding the 9-Axis Sensor Ecosystem

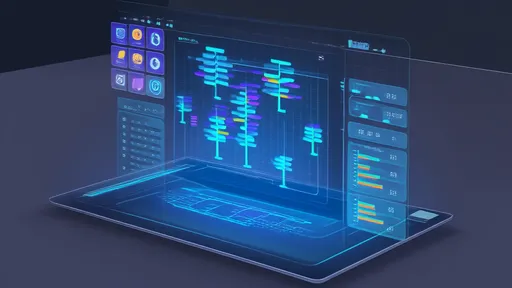

Modern motion controllers pack an extraordinary amount of technology into compact form factors. The 9-axis designation refers to the combination of 3-axis accelerometers (measuring linear acceleration), 3-axis gyroscopes (tracking angular velocity), and 3-axis magnetometers (detecting magnetic field orientation). Together, these sensors create what's known as an Attitude and Heading Reference System (AHRS), capable of determining both orientation and movement relative to Earth's gravity and magnetic field.

The accelerometers measure proper acceleration in the X, Y, and Z axes, allowing the system to understand which way is "down" due to gravity and how the controller is moving through space. Gyroscopes complement this by measuring rotational velocity around these same axes, providing crucial data about how the controller is being tilted or turned. Magnetometers add the final piece of the puzzle by sensing the Earth's magnetic field, giving the system a fixed reference point to determine compass heading and compensate for gyroscope drift.

The Calibration Imperative

Raw sensor data is inherently noisy and prone to various types of errors. Each sensor in the IMU has unique characteristics that must be accounted for through calibration. Accelerometers may show slight variations in their zero-g offset (the reading they produce when stationary). Gyroscopes often exhibit bias errors where they report small rotation values even when perfectly still. Magnetometers are particularly sensitive to environmental interference from nearby electronics or metal objects.

Without proper calibration, these imperfections compound rapidly, leading to the dreaded "drift" phenomenon where the virtual representation of the controller slowly diverges from its real-world position. In VR applications, this can break immersion completely as users find their virtual hands floating away or pointing in wrong directions. For motion-controlled gaming, uncalibrated sensors result in imprecise inputs that make accurate gameplay impossible.

Factory Calibration: The First Line of Defense

Quality motion controller manufacturers perform extensive factory calibration on every unit before shipment. This process typically involves mounting the controller in a precisely known orientation and collecting sensor data across various positions and temperatures. Factory calibration establishes baseline compensation values for:

Accelerometer zero-g offsets and sensitivity scaling factors. Gyroscope bias offsets and temperature compensation coefficients. Magnetometer hard iron offsets (permanent magnetic distortions) and soft iron corrections (magnetic field distortions caused by nearby materials). These calibration parameters are stored in the controller's firmware and applied to all subsequent sensor readings.

The Role of User-Performed Calibration

While factory calibration handles the fundamentals, user-performed calibration remains essential for optimal performance. Environmental factors like local magnetic disturbances or temperature variations can affect sensor behavior. Most high-end motion controllers include built-in calibration routines that guide users through specific movements to fine-tune the sensors.

A typical magnetometer calibration might involve slowly rotating the controller in figure-8 patterns to map the local magnetic environment. Gyroscope calibration usually requires placing the controller on a stable surface to measure its bias offsets. Some systems implement continuous background calibration that refines parameters during normal use whenever the controller is determined to be at rest.

Advanced Calibration Techniques

Professional-grade motion tracking systems employ even more sophisticated calibration methods. Temperature compensation is critical, as sensor characteristics change with heat buildup during extended use. Some systems use onboard temperature sensors to apply dynamic corrections based on pre-measured thermal response curves.

Sensor fusion algorithms like Madgwick or Mahony filters combine data from all three sensor types, weighting each input based on its current reliability. These algorithms automatically detect and compensate for temporary sensor disturbances, such as when a magnetometer reading becomes unreliable due to proximity to a metal object.

Cross-axis sensitivity calibration accounts for how sensors may respond slightly to movements along axes they're not primarily designed to measure. This involves precisely moving the controller along each axis while monitoring all sensor outputs to build a comprehensive correction matrix.

Calibration Challenges in Consumer Devices

Consumer motion controllers face unique calibration challenges compared to professional equipment. Cost constraints limit the quality of sensors that can be used, making robust calibration even more critical. The wide variety of usage environments - from magnetically noisy living rooms to outdoor spaces - requires calibration routines that can adapt to diverse conditions.

Perhaps most challenging is designing calibration procedures that average users can successfully perform without specialized knowledge. This has led to the development of automated calibration techniques that run transparently in the background whenever the system detects favorable conditions (like when the controller is left stationary for several seconds).

The Future of Motion Controller Calibration

As motion tracking technology advances, we're seeing new approaches to sensor calibration. Machine learning algorithms can now analyze sensor data patterns to detect when recalibration is needed and even predict future drift. Some systems use camera-based tracking or external beacons to provide periodic ground truth measurements that keep the IMU calibrated during use.

Emerging standards like the Spatial Calibration Protocol aim to create unified calibration procedures across different manufacturers' devices. This would allow motion controllers from different vendors to work together seamlessly in shared VR spaces with consistent tracking accuracy.

The ultimate goal is achieving what researchers call "plug-and-play" calibration - systems so robust that they require no explicit user intervention while maintaining sub-degree tracking accuracy indefinitely. While we're not quite there yet, recent advancements suggest this may become reality within the next generation of motion controllers.

For now, understanding and properly executing calibration procedures remains the key to getting the best performance from 9-axis motion controllers. Whether you're a VR enthusiast, game developer, or industrial user, taking the time to calibrate properly makes the difference between frustrating drift and magical, immersive motion tracking.

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025