The realm of optical engineering has witnessed significant advancements in recent years, with Pancake lenses emerging as a pivotal technology in compact optical systems. These lenses, characterized by their folded light path design, have revolutionized the way we approach light efficiency in applications ranging from virtual reality headsets to advanced camera systems. At the heart of this innovation lies the critical metric of light efficiency utilization, a parameter that dictates the performance and practicality of these lenses in real-world scenarios.

Pancake lenses derive their name from their unique flattened structure, which contrasts sharply with traditional bulky lens assemblies. By employing a folded optical path, these lenses significantly reduce the physical footprint while maintaining optical performance. However, the efficiency with which they utilize incoming light remains a subject of intense research and development. Light efficiency in Pancake lenses isn't merely about brightness; it encompasses factors such as polarization management, ghost image suppression, and overall system throughput.

The physics behind Pancake lens light efficiency involves complex interactions between polarized light and optical coatings. Unlike conventional lenses where light travels straight through elements, Pancake lenses require light to make multiple reflections within their compact structure. Each reflection presents an opportunity for light loss, primarily through absorption and imperfect reflections. Manufacturers combat these losses through advanced coating technologies that can maintain polarization states while maximizing reflectivity at critical surfaces.

Modern Pancake lenses often incorporate quarter-wave plates and reflective polarizers to manage light propagation efficiently. The quarter-wave plate converts linearly polarized light into circularly polarized light and vice versa, enabling the folded path design. Meanwhile, the reflective polarizer ensures that only light with the desired polarization state continues through the system. This intricate dance of polarization states, when properly engineered, can achieve light efficiency percentages that rival traditional lens designs despite the additional complexity.

Real-world applications demand careful balancing between light efficiency and other optical parameters. In virtual reality systems, for instance, insufficient light throughput can lead to dim displays that break immersion, while excessive light loss might require brighter display panels that increase power consumption and generate more heat. Engineers must also consider how light efficiency affects the system's modulation transfer function (MTF), ensuring that resolution and contrast aren't sacrificed in pursuit of compactness.

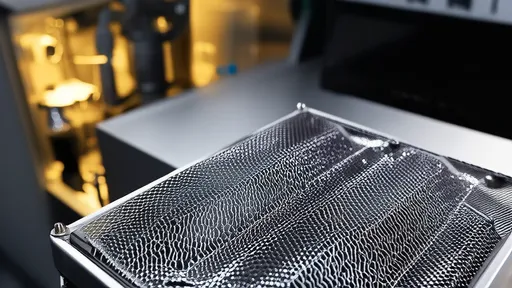

The manufacturing tolerances for high-efficiency Pancake lenses are exceptionally tight. A misalignment of just a few micrometers in the optical stack can cause substantial light loss through leakage or incorrect polarization conversion. This precision requirement has driven innovations in assembly techniques, including active alignment processes where optical elements are adjusted in real-time while measuring light throughput. Such meticulous assembly contributes significantly to the final product's light efficiency rating.

Material science plays an equally crucial role in optimizing Pancake lens performance. The substrates for optical elements must exhibit exceptional homogeneity to prevent wavefront distortion, while coating materials need to maintain their performance characteristics across various environmental conditions. Recent developments in nanostructured optical materials have opened new possibilities for enhancing light efficiency beyond what traditional thin-film coatings can achieve.

As Pancake lenses find applications in increasingly diverse fields, from medical imaging to military optics, the pressure to improve their light efficiency continues to grow. Researchers are exploring novel architectures that might reduce the number of required reflections while maintaining the compact form factor. Others are investigating advanced materials that could minimize absorption losses at each reflection point. The future may see Pancake lenses that approach the theoretical limits of light efficiency, making them viable for even the most demanding optical applications.

The measurement and characterization of light efficiency in Pancake lenses present their own set of challenges. Traditional light measurement techniques often fail to account for the polarization-dependent behavior of these systems. Specialized testing setups that can isolate and measure specific polarization states are essential for accurate efficiency assessments. These measurements not only verify product specifications but also guide ongoing optimization efforts during the development phase.

Consumer electronics manufacturers have become particularly interested in Pancake lens technology as they push for slimmer form factors in augmented and virtual reality devices. The light efficiency directly impacts battery life and display visibility, making it a key differentiator in competitive markets. Some industry leaders have begun quoting light efficiency metrics in their product specifications, signaling its importance to end-users who prioritize performance and energy efficiency.

Looking ahead, the evolution of Pancake lens technology will likely focus on breaking through current light efficiency barriers. Techniques borrowed from waveguide optics and metasurface technology may provide the necessary breakthroughs. As these innovations mature, we can anticipate Pancake lenses that not only match but potentially surpass conventional optics in light efficiency while maintaining their signature compact design. This progress will undoubtedly open new possibilities in fields where size constraints previously limited optical performance.

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025