The renewable energy sector is witnessing a groundbreaking innovation with the development of self-healing solar panels. Researchers have successfully integrated microfluidic channels into photovoltaic (PV) cells, enabling the automatic replenishment of photosensitive agents. This advancement promises to significantly extend the lifespan of solar panels while reducing maintenance costs and improving efficiency.

Traditional solar panels suffer from gradual degradation due to environmental factors such as UV exposure, temperature fluctuations, and mechanical stress. Over time, the photosensitive materials within the cells break down, leading to diminished performance. The new self-healing technology addresses this issue by mimicking biological systems, where damage triggers an automatic repair response.

How It Works

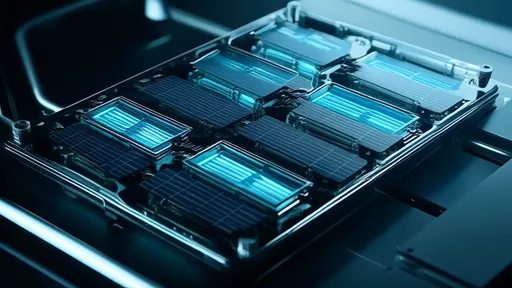

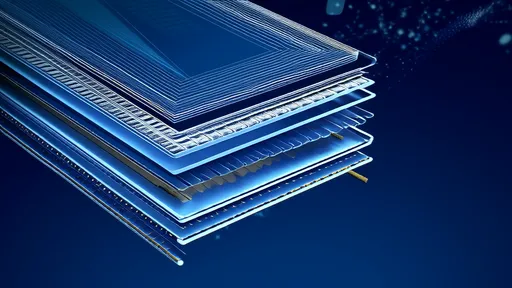

The core of this innovation lies in the microfluidic channels embedded within the solar panel structure. These tiny channels are filled with a liquid solution containing photosensitive molecules. When the photovoltaic material becomes damaged or degraded, the microfluidic system detects the change and releases the healing agents to the affected area. The photosensitive molecules then bond with the damaged material, effectively restoring its functionality.

This process is entirely autonomous, requiring no external intervention. The microfluidic system is designed to be highly responsive, ensuring that repairs are carried out swiftly and efficiently. By maintaining the integrity of the photosensitive layer, the solar panel can operate at near-optimal levels for much longer periods than conventional panels.

Advantages Over Conventional Systems

One of the most significant benefits of this technology is its potential to reduce the frequency of panel replacements. Solar farms and rooftop installations often face high costs associated with maintaining and replacing degraded panels. With self-healing capabilities, these expenses could be drastically cut, making solar energy more economically viable.

Additionally, the microfluidic approach minimizes waste. Traditional solar panels that have degraded beyond repair often end up in landfills, contributing to environmental pollution. By extending the usable life of each panel, the self-healing system helps reduce the volume of solar waste, aligning with global sustainability goals.

Challenges and Future Prospects

Despite its promise, the technology is not without challenges. The integration of microfluidic channels into existing solar panel designs requires precise engineering to ensure that the channels do not interfere with the panel's light absorption capabilities. Researchers are also working on optimizing the healing agents to ensure they remain stable under various environmental conditions.

Looking ahead, the team aims to scale up the technology for commercial use. Pilot projects are already underway to test the durability and efficiency of self-healing panels in real-world conditions. If successful, this innovation could revolutionize the solar energy industry, paving the way for more resilient and sustainable energy solutions.

Industry Reactions and Potential Impact

The renewable energy community has greeted this development with enthusiasm. Industry experts believe that self-healing solar panels could become a standard feature in future PV systems, particularly in regions with harsh climates where panel degradation is a persistent issue. The technology also holds promise for space applications, where maintenance-free energy systems are highly desirable.

As the world continues to shift toward renewable energy, innovations like self-healing solar panels will play a crucial role in ensuring the reliability and efficiency of green power sources. This microfluidic approach not only enhances performance but also contributes to the broader goal of creating sustainable and low-maintenance energy infrastructure.

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 18, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025